Our products

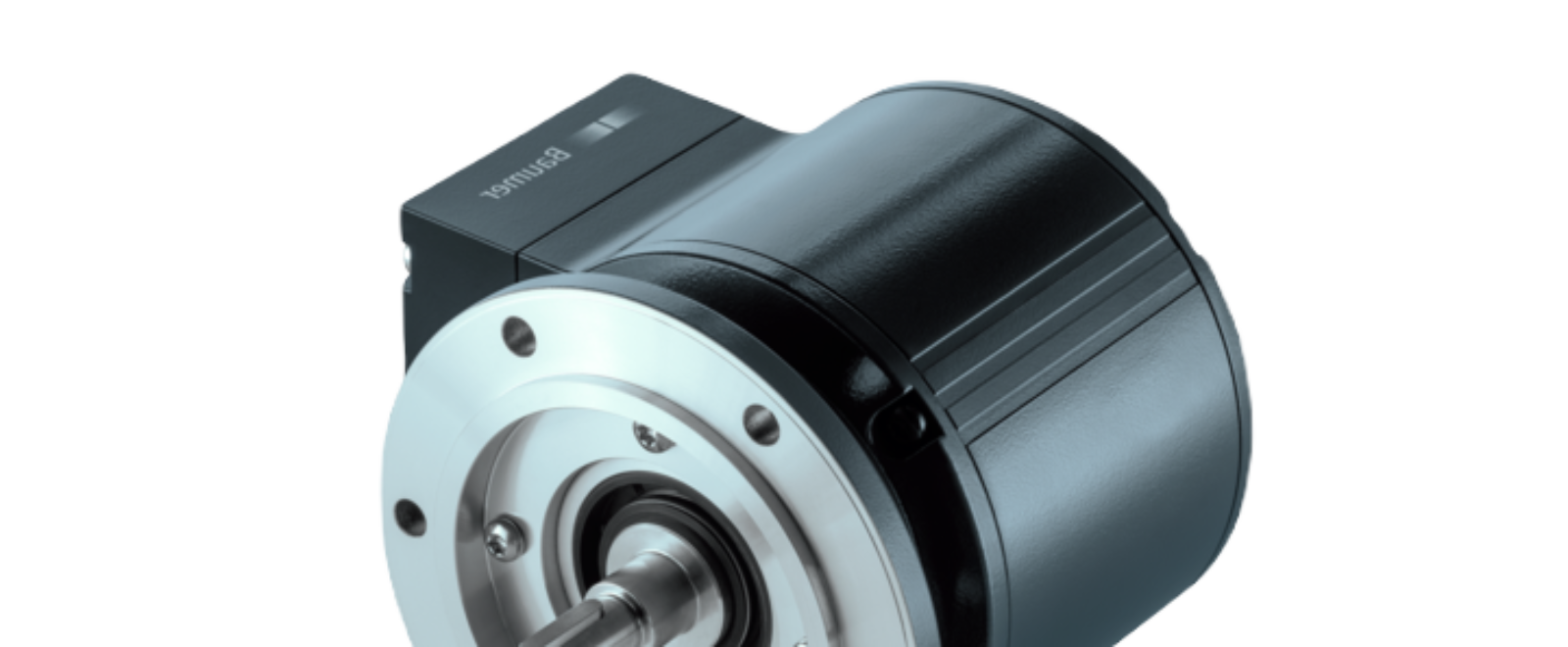

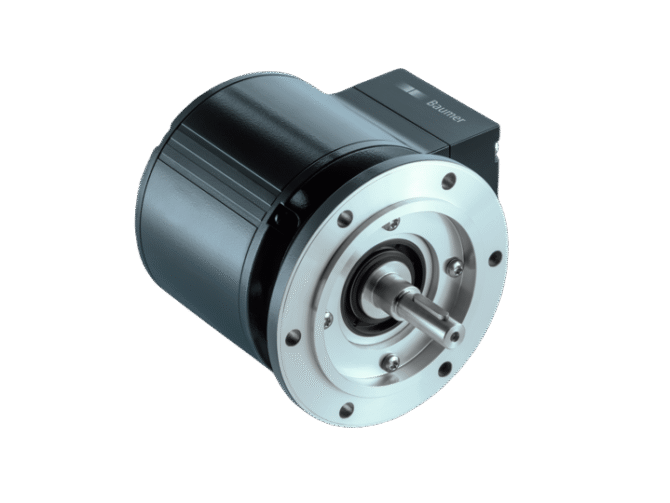

PMG10 – PROFIBUS

- Type: Solid shaft

- Size: ø11 mm

- Interface/Protocol: PROFIBUS

- Flange size: ø115 mm

- Steps per revolution: 8192 / 13 bit

- Number of revolutions: 65536 / 16 bit

PMG10 – PROFINET

- Type: Solid shaft

- Size: ø11 mm

- Interface/Protocol: PROFINET

- Flange size: ø115 mm

- Steps per revolution: 8192 / 13 bit

- Number of revolutions: 65536 / 16 bit

PMG10 – SSI

- Type: Solid shaft

- Size: ø11 mm

- Interface/protocol: SSI

- Flange size: ø115 mm

- Steps per revolution 1048576 / 20 bit

- Number of revolutions 1048576 / 20 bit

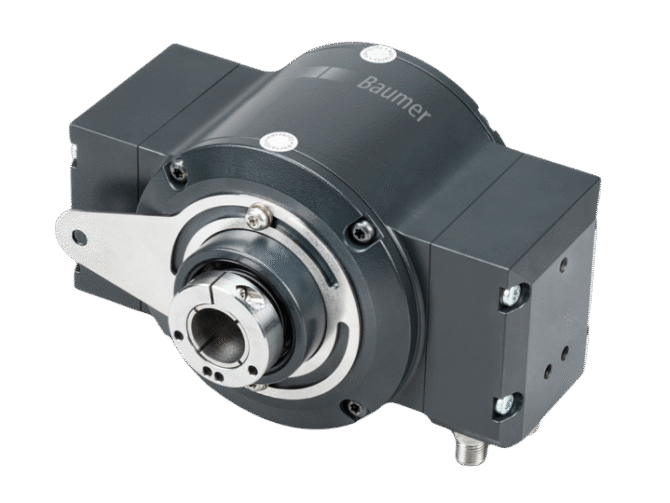

HMG10-T PROFIBUS

- Type: Through hollow shaft

- Size: ø16...20 mm

- Interface/Protocol: PROFIBUS DPV0/V2

- Flange size: ø105 mm

- Steps per revolution: 8192 / 13 bit

- Number of revolutions: 65536 / 16 bit

HMG10-T PROFINET

- Type: Through hollow shaft

- Size: ø16...20 mm

- Protocol: PROFINET

- Flange size: ø105 mm

- Steps per revolution: 8192 / 13 bit

- Number of revolutions: 65536 / 16 bit

HMG10-T SSI

- Type: Through hollow shaft

- Size: ø16...20 mm

- Interface/Protocol: SSI

- Flange size: ø105 mm

- Steps per revolution: 1048576 / 20 bit

- Number of revolutions: 1048576 / 20 bit

HMG10-B PROFIBUS

- Type: Blind Hollow shaft or Cone Shaft 1:10

- Size: Ø12…20 mm or Ø17 mm

- Interface/Protocol: DPV0/V2

- Flange size: ø105 mm

- Steps per revolution: 8192 / 13 bit

- Number of revolutions: 65536 / 16 bit

HMG10-B PROFINET

- Type: Through Hollow shaft

- Size: Ø16…20 mm

- Protocol: PROFINET

- Flange size: ø105 mm

- Steps per revolution: 8192 / 13 bit

- Number of revolutions: 65536 / 16 bit

HMG10-B SSI

- Type: Blind Hollow shaft or Cone Shaft 1:10

- Size: Ø12…20 mm or Ø17 mm

- Protocol: SSI

- Flange size: ø105 mm

- Steps per revolution: 1048576 / 20 bit

- Number of revolutions: 1048576 / 20 bit

Did you not find what you were looking for?

Contact us and we will look for the right solution together!

InquireAccessoires

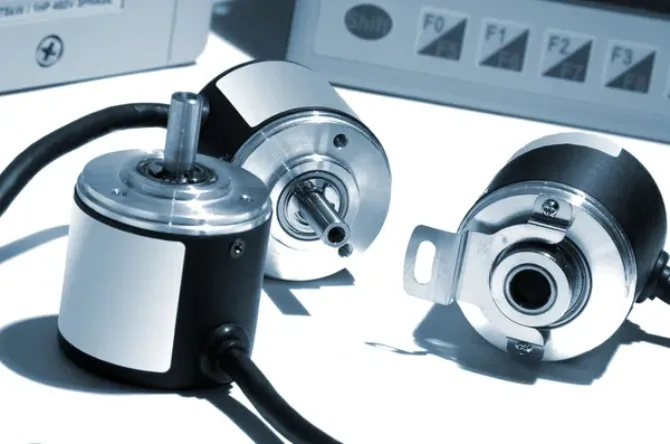

What is an absolute encoder?

An absolute encoder is a type of rotary position sensor that generates a unique code for each shaft position, allowing it to detect and track absolute position values even after power loss. Unlike incremental encoders, which only track movement, absolute encoders provide the exact shaft angle at any given time, essential for systems requiring precision and safety.

Available in single- and multi-turn versions, absolute encoders are the preferred choice for modern automation systems that require reliable real-time data. Their integrated interface protocols, such as SSI, PROFINET, and EtherCAT make them versatile for many control systems.

Why choose Baumer absolute encoders?

Euro HÜBNER Benelux B.V. is the leading distributor of Baumer encoder products in the region. Baumer’s engineering quality, paired with Euro HÜBNER’s in-depth expertise, ensures high resolution, low latency, and long-term durability in all applications.

Our absolute rotary encoders include advanced designs for challenging industrial environments. Each encoder offers excellent signal stability, bit precision, and compact housing options for easy integration. We also assist with cable, wiring, and communication setup to ensure full system compatibility.

Single turn vs multi-turn encoders: what’s the difference?

A single-turn encoder provides position data within one revolution of the shaft. It is suitable for applications where a single rotation is enough to determine position.

Multi-turn absolute encoders, on the other hand, use internal gear or magnetic technology to count multiple shaft revolutions. This makes them ideal for tracking full rotational cycles across larger distances or vertical travel, such as in cranes or lifts. With hall and magnet-based designs, these encoders track multiple rotations even without power.

Both options are available with protocols such as SSI, CANopen, BiSS, and Ethernet-based formats.

Common protocols and interfaces for absolute encoders

Encoders use a wide variety of interfaces and communication protocols. Choosing the right one depends on your system’s design, output format, and control requirements.

Some of the most common interfaces include:

- SSI (Synchronous Serial Interface): A widely used digital interface for industrial sensors.

- BiSS: A high-speed, bidirectional protocol ideal for demanding automation applications.

- PROFINET and EtherCAT: Ethernet-based systems offering real-time data transmission.

- CANopen and DeviceNet: Popular in distributed systems for machine control.

- IO-Link: A smart point-to-point communication system that improves integration and diagnostic capabilities.

Where are absolute encoders used?

Absolute encoders are indispensable in automation, robotics, CNC machines, printing, and industrial positioning systems. Their high resolution and precise angle tracking make them the go-to sensor in fields where every movement counts.

Typical applications include:

- Measuring the position of robotic arms

- Monitoring rotary shafts in motors or drives

- Elevation tracking in construction and lift systems

- Wind turbine pitch control

- Packaging systems with parallel movements

In every application, encoder feedback ensures accurate motion control and system safety.

Advantages of using absolute rotary encoders

Absolute rotary encoders offer several benefits that outperform traditional incremental sensors:

- Even after a power interruption, they retain their exact position

- High resolution and stable signal output

- Reduced wiring complexity with modern protocols

- Less calibration time, no need for homing after restart

- Support for analogue and digital interfaces

They help you determine the exact location of moving components without guesswork, a critical advantage in smart manufacturing.

How to select the right encoder absolute

When choosing an encoder absolute, consider the following:

- Type: Single turn and multi turn options

- Required interface: SSI, EtherCAT, PROFIBUS, etc.

- Shaft requirements: Solid, blind, or through-shaft

- Output signal type: Analogue, digital, or serial

- Operating environment: IP rating, distance, vibration, and temperature tolerance

- Compatibility with your factory or field control system

Euro HÜBNER helps match each encoder to your unique application needs, ensuring system reliability and performance.

Euro HÜBNER Benelux B.V.: your trusted partner in absolute encoder technology

At Euro HÜBNER Benelux B.V., we provide:

- Extensive stock of Baumer encoders

- Support for obsolete models and repairs

- Technical consultancy and on-site support

- Same-day delivery options in urgent cases

- Professional advice for system upgrades

Whether you’re designing a new automation system or upgrading an existing one, we supply the best encoder technology for maximum uptime.

Accessories and add-ons

To ensure optimal performance, we also supply accessories for encoder Baumer models:

- Torque arms (insulated and standard)

- Couplings (K35, K50, K60)

- HEK8 cables

- Carbon brushes (GT9, GTB9, GMP1.0, TDP series)

Our full range ensures a seamless integration with your system.

Looking for a custom solution?

We want to help you!

Contact

Benefits

Large stock of products

In our warehouse in Venlo, we maintain a large stock of incremental encoders, encoders absolute, tacho generators, brakes, brake parts and force measuring systems. Our company is based in Venlo, in the centre of the Benelux. Due to this location, we are able to deliver on a very sharp time schedule. When urgency is requested, we can deliver within 24 hours to your company in the Benelux, or even arrange a taxi for delivery within a few hours. Because we keep such a large stock in our warehouse, we are able to process and deliver your order usually very fast.

Total solutions

Euro HÜBNER Benelux B.V. offers a range of total solutions to meet to the specific needs of our clients. These solutions encompass various aspects from technical consultancy to product selection, installation and support services.

Design and Engineering

We assist clients in the design and engineering phase of their projects. Our team of experts collaborates closely with our clients to understand their requirements and develop customized solutions that meet their specific needs.

Product testing and Validation

Our company conducts rigorous testing and validation procedures to ensure that the products meet industry standards and regulatory requirements. This helps in verifying the quality, durability and reliability of the solutions we provide.

Customized Solutions for Various Industries

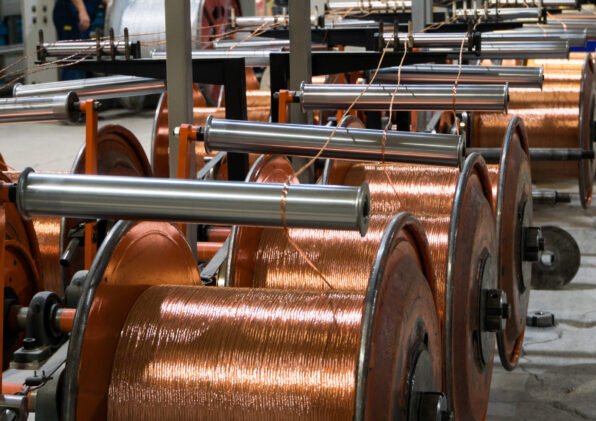

Euro HÜBNER Benelux B.V. serves clients from diverse industries, including steel industry, paper industry, marine on- and offshore, motion control, industrial and construction industries. We customize solutions to meet the specific demands and challenges of each industry, providing reliable and efficient products.

Quality Assurance

Euro HÜBNER Benelux B.V. is committed to delivering products and services of the highest quality. We adhere to stringent quality control measures throughout our operations, from design and manufacturing to installation and support. By prioritizing quality assurance, we aim to provide customers with reliable, durable, and high-performing solutions.

Frequently asked questions about absolute encoders

-

What’s the difference between analog and digital encoders?

Encoders may output signals as either analog or digital. Digital signal encoders provide binary output, while analog types provide continuous signal ranges to represent position.

-

Can I use an absolute encoder with an SSI interface in my automation system?

Yes. SSI is a standard serial communication protocol compatible with many controllers.

-

What makes Baumer encoders suitable for industrial environments?

Their robust housing, precise output, and reliable data transmission make them ideal for heavy-duty applications.

Markets & Technology

Require any help?

Feel free to call or e-mail us, and we will get back to you as soon as possible.

Service & Repair

Euro HÜBNER Benelux B.V. provides high quallified service and repair solutions.

-

-

-