Optimisation of the brakes outcome / summary

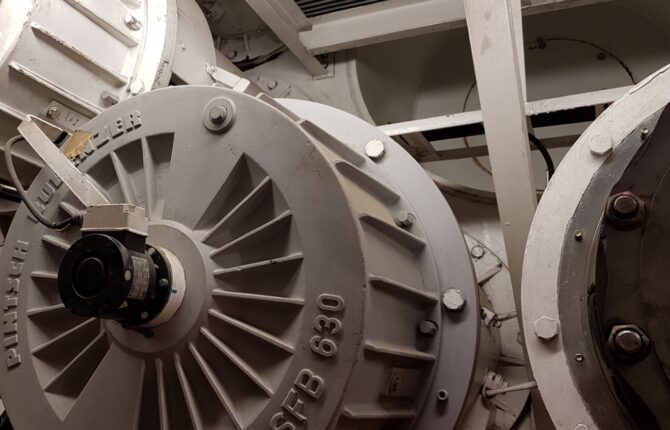

On this crane vessel, we optimised the brakes by correctly replacing parts and providing training to our client. Our client owns several large crane vessels that are not equipped with “standard” brakes. Some of these brakes were worn out, and parts needed to be replaced. These vessels require a certificate to perform a task, including a well-executed function test (load-test). However, this test kept failing, and even after replacing the components, the company’s own engineers couldn’t get the brakes in order. The client contacted us to help resolve the recurring failure of the load-test. A service visit was promptly scheduled.

What does that entail?

Firstly, internal information is gathered at Euro Hübner; what is the known history of the ship, what do we already know about the installation, and we investigate what might be causing the load-test to fail (e.g., overload, reduced resistance, or braking force). Then, our engineer goes on-site together with the company’s own engineering and/or the superintendent to see if the proposed solution actually works. (This meeting serves at the same time as a bespoke training.) Together with the company’s engineers, our engineer replaced a few brakes.

Additionally, the engineers received instructions from our engineer on how to troubleshoot this themselves in the future. As these parts were in stock in Venlo and knowledge was effectively transferred, the company’s engineers were able to adjust the remaining 30 brakes themselves.

Require any help?

Feel free to call or e-mail us, and we will get back to you as soon as possible.

Service & Repair

Euro HÜBNER Benelux B.V. provides high quallified service and repair solutions.

-

-

-