Revision of a Belt Weigher result / summary

Our client has an existing production line. Deviant measurement values were observed in this line. Therefore, these values needed to be restored to their original – correct – state. The measuring bearings were dismantled and sent to our service department in Venlo. Here, they were thoroughly tested, measured, and ultrasonically cleaned. A deviation in the resistance strip was identified and this was the reason for replacement. We ordered a new force measuring bearing (LMGZ310), and within a week, it was installed and calibrated at the client’s site.

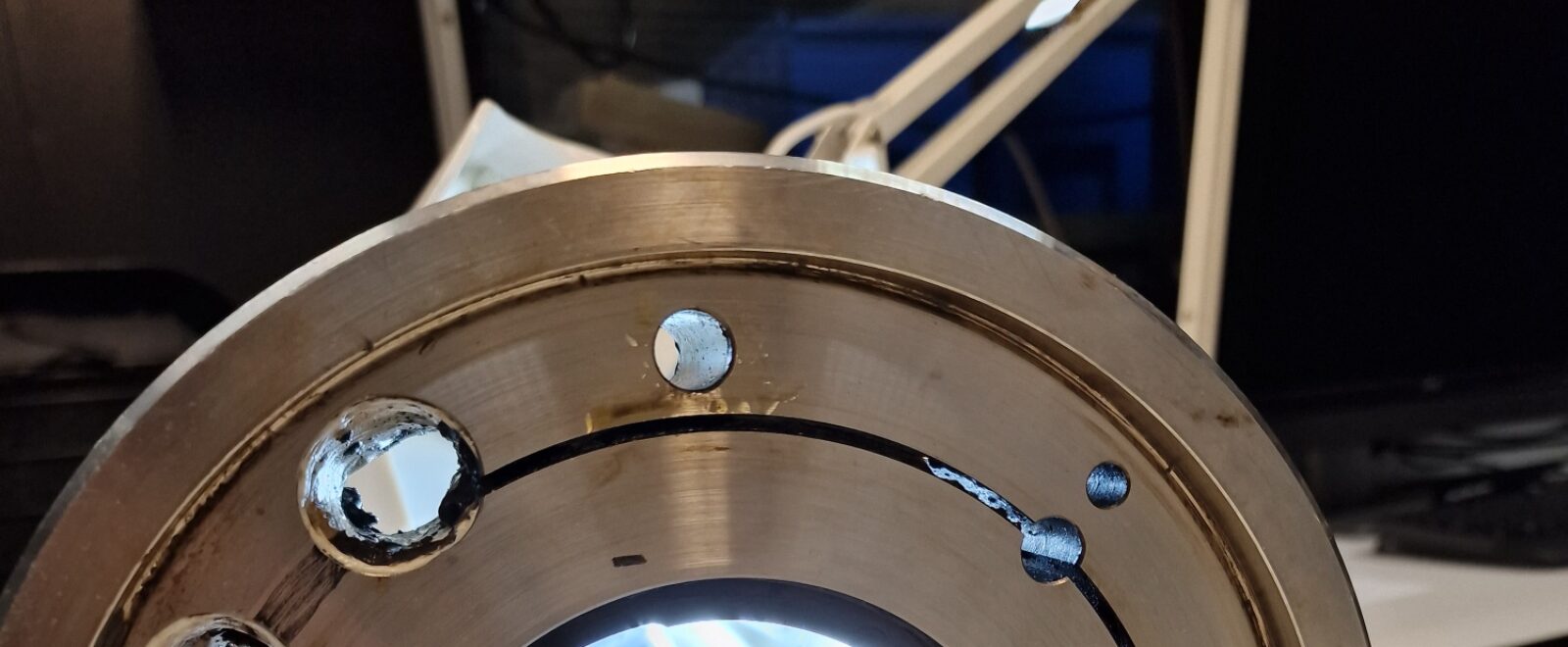

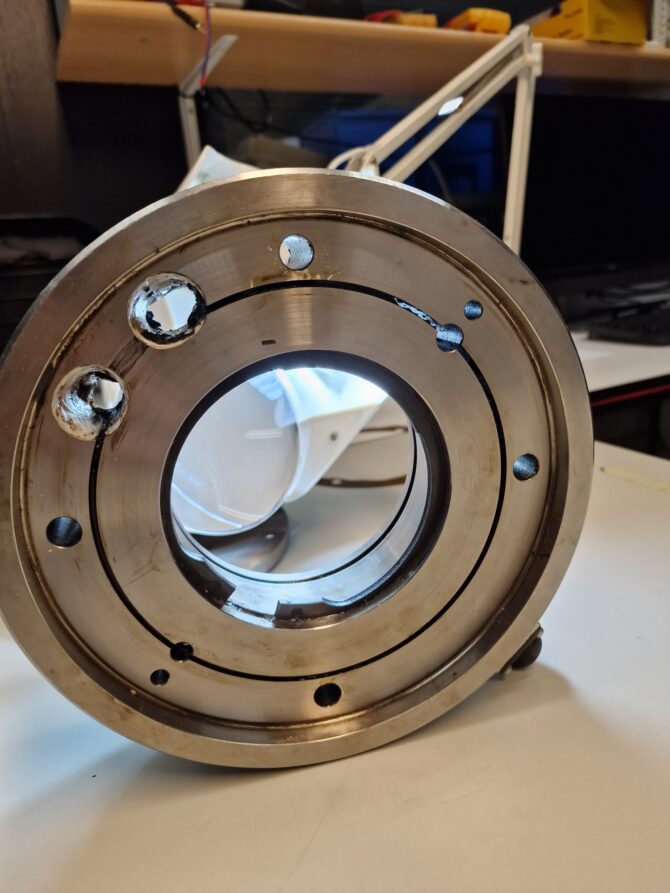

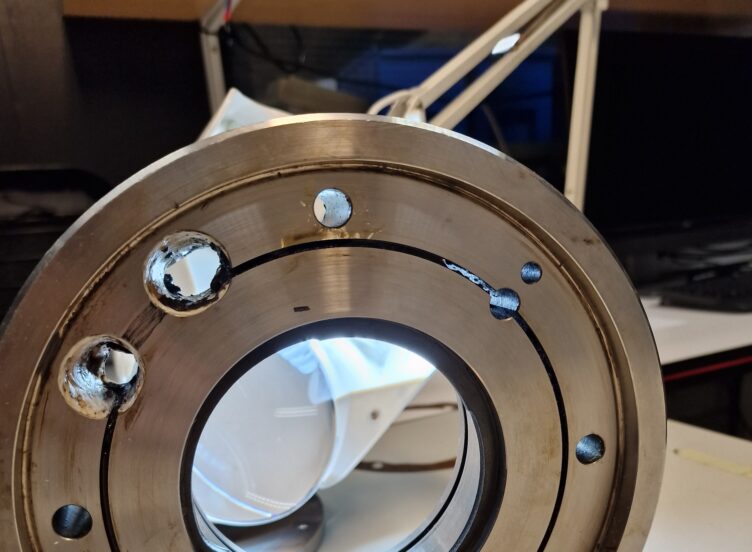

Tested, measured and ultrasonically cleaned

Here, they were thoroughly tested, measured, and ultrasonically cleaned. A deviation in the resistance strip was identified and this was the reason for replacement. We ordered a new force measuring bearing (LMGZ310), and within a week, it was installed and calibrated at the client’s site.

Other Cases

Require any help?

Feel free to call or e-mail us, and we will get back to you as soon as possible.

Service & Repair

Euro HÜBNER Benelux B.V. provides high quallified service and repair solutions.

-

-

-