In today’s heavy-duty industries — such as offshore, onshore, and steel production — precision and uptime are non-negotiable. Central to that reliability is the encoder. These compact yet powerful devices translate mechanical motion into digital signals, providing critical feedback for automation systems, motors, and control units.

Whether mounted on a shaft, installed in harsh outdoor environments, or integrated into robotic lines, encoders are indispensable for accurate motion control. Unfortunately, common encoder failures are a leading cause of downtime in industrial settings. Understanding how and why encoders fail is key to preventing costly interruptions, equipment damage, and safety risks.

What are the most common causes of encoder failures?

We would like to share the four most common encoder failures below.

Disc contamination and signal instability

One of the most prevalent causes of encoder failure is contamination of the internal disc—the component responsible for generating the encoder’s output signal. When exposed to dirt, oil, or fine metal particles, the disc may send faulty or unstable signals to the control system. This is especially problematic in steel mills, where dust and grease are ever-present.

Shaft misalignment and bearing wear

Another frequent issue is shaft misalignment. If the encoder is not properly mounted or if the shaft is subject to excess load or vibration, it can stress internal components such as bearings. Over time, this causes mechanical degradation that leads to signal instability or total encoder failure.

Wiring, cable, and interference issues

Electrical issues are just as critical. Poor wiring, unshielded cables, and incorrect grounding can all lead to electromagnetic interference or damaging voltage spikes. In offshore applications, where power systems are complex and often exposed to the elements, this risk is amplified.

Environmental shock and vibration

Constant vibration or sudden mechanical shocks can drastically shorten the encoder’s lifespan. Using encoders that are not designed to handle such conditions will inevitably result in malfunction or breakdown.

How to prevent common encoder failures in harsh environments

Choose the right encoder type

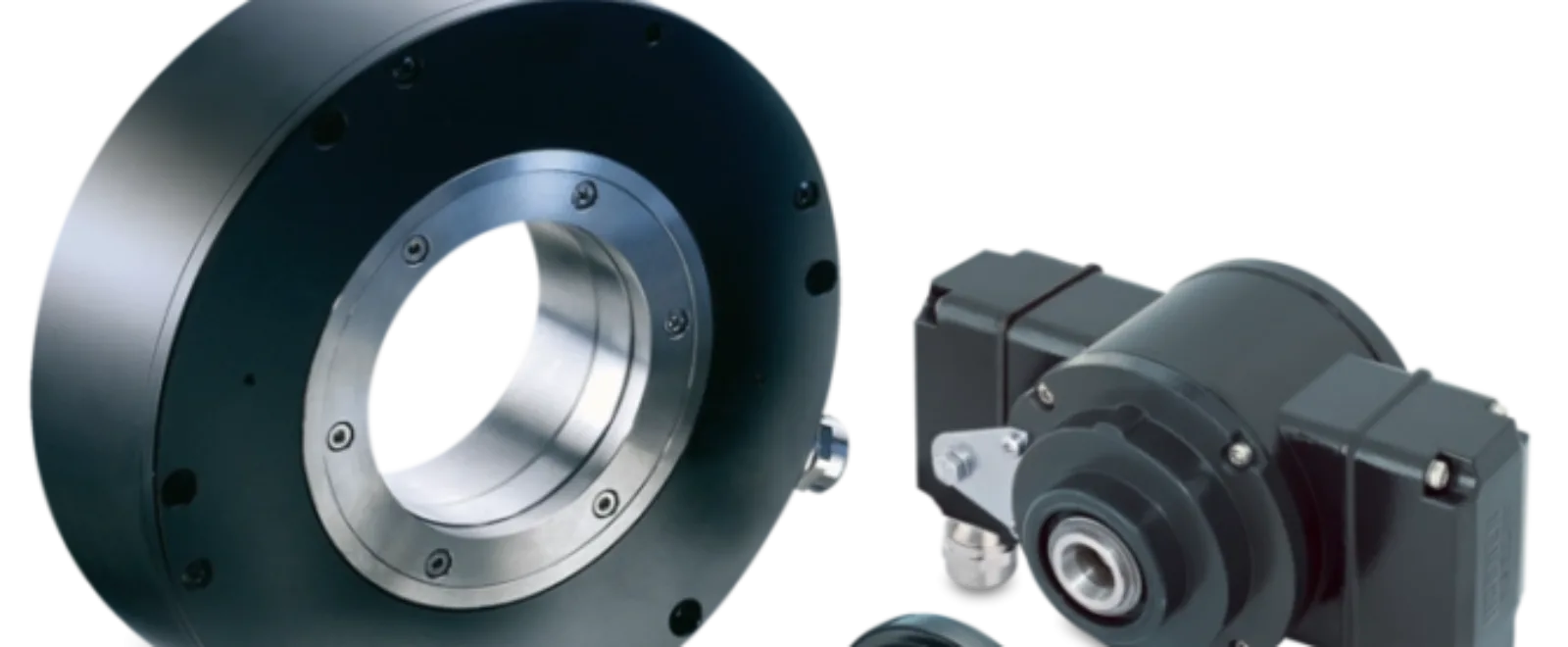

Preventing common encoder failures starts with selecting the right hardware. In offshore or steel environments, ruggedized encoders with sealed housings and high vibration resistance are essential. Euro Hübner offers various models designed for harsh conditions—see the explanation of what are encoders to learn more.

Ensure proper mounting

Misalignment between the encoder and the motor shaft is a major source of encoder stress. Always use flexible couplings and adhere to manufacturer specifications for torque and alignment. Proper mounting can significantly extend the life of the encoder and prevent common failure modes.

Use shielded wiring and cables

Proper wiring is critical. Use industrial-grade cables that are shielded and resistant to oil and abrasion. Keep encoder wiring physically separate from high-voltage motor lines to minimize signal disruption. These precautions also help avoid voltage surges and interference from nearby equipment.

Ground systems and monitor voltage

To protect electronics, ensure all encoder systems are properly grounded. Use surge protectors and avoid sharing encoder power lines with motor drives. Spikes in voltage can irreversibly damage internal components if not mitigated.

Encoder failures in offshore and steel industry applications

Offshore environments

In offshore environments, encoders must endure humidity, salt, and continuous machine movement. Choosing IP-rated models designed for marine use helps avoid common failures caused by environmental exposure.

Steel plant conditions

Steel plants expose encoders to high heat, slag, and metallic dust. Encoders installed in these settings should be enclosed and positioned away from direct exposure to hot zones. For example, SSI encoder models using fiber-optic communication can help reduce signal degradation in electromagnetically noisy environments.

Selecting between encoder types

It’s crucial to choose the right encoder for your setup. Absolute encoder models retain position during power loss, while incremental encoder models provide high-resolution feedback but are more vulnerable to cable faults and signal noise.

For speed or direction feedback in demanding environments, combining an encoder with a tachometer can enhance reliability. These encoder-tachometer hybrids are especially useful in steel or offshore applications where accuracy under dynamic conditions is essential. Discover how encoder tachometer technology supports accurate feedback in dynamic environments in our article on tacho generators.

Troubleshooting signs of common encoder failures

Fluctuating feedback signals

Slight feedback drift or irregular signals can be early signs of disc misalignment or bearing damage. These symptoms are often overlooked until the encoder fully fails.

Cable and wiring deterioration

Wear and tear on wiring can introduce faults that lead to intermittent signal loss. Regular inspection of cables and connectors should be part of every maintenance plan.

Real-world case: motor interference

At one steel facility, operators faced frequent encoder errors on the production line. The issue was traced to unshielded wiring laid alongside servo motors. After rerouting and shielding the wiring, encoder reliability improved dramatically.

How reliable partners help reduce common encoder failures

Preventing common encoder failures isn’t just about hardware—it’s about choosing the right suppliers. Euro Hübner collaborates with trusted names like Baumer Nederland, Dellner Bubenzer, and FMS to provide components that perform in the world’s harshest environments.

In addition to durable hardware, expertise in product selection, mounting, and diagnostics can prevent issues before they arise. That’s why Euro Hübner also supports clients with guidance tailored to specific industrial sectors.

Looking for a long-term solution to persistent encoder problems? Contact Euro Hübner for a tailored consultation with one of our application specialists.