Our products

SFB16

SFB10

SFB6,3

Coil – SFB

Cover Housing – SFB

Coil Spring – SFB

Screw and sealing set – SFB

Coil – KFB

Cover Housing – KFB

Coil Spring – KFB

Screw and sealing set – KFB

BMM2 BMM10 Brake Monitoring Module

BCU2001

Did you not find what you were looking for?

Contact us and we will look for the right solution together!

InquireAt Euro Hübner, we offer a wide range of brakes

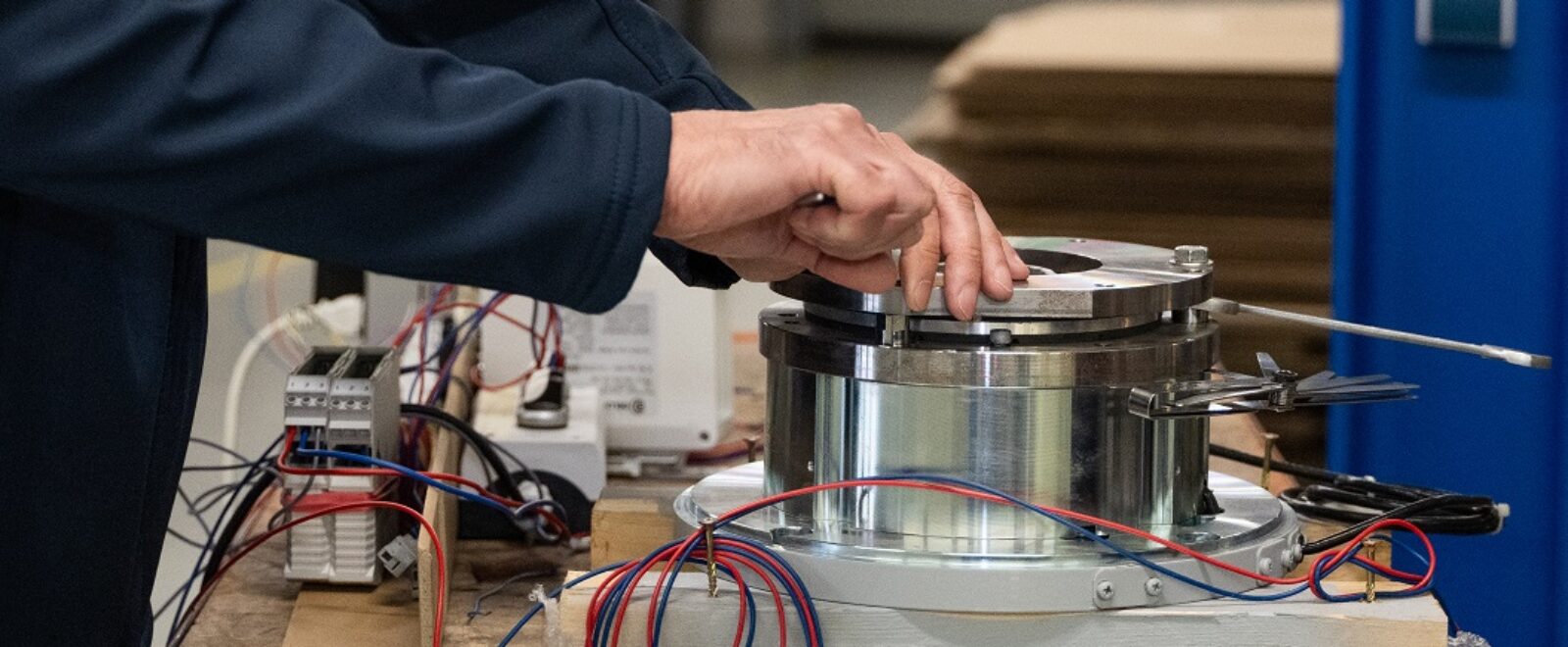

Dellner Bubenzer is a leading supplier of high-quality electromagnet braking systems and electronic parts. At Euro HÜBNER, we offer a wide range of electromagnetic brakes to meet the needs of various industries and applications. Our brakes are known for their superior performance, reliability, and tailored solutions. With over 30 years of experience in brake engineering and applications, Euro HÜBNER has built an extensive product range that supports safe, efficient, and durable motion control.

Our in-house expertise enables us to identify and supply the ideal electromagnetic brake systems for demanding mechanical and electrical requirements. Every unit—such as the trusted SFB and KFB series—is rigorously tested by manufacturers like Dellner Bubenzer to ensure long-term performance and compliance. These systems deliver precise speed and torque control, acting as key safety components in cranes, winches, conveyor systems, and wind turbines.

What Is an Electromagnetic Brake?

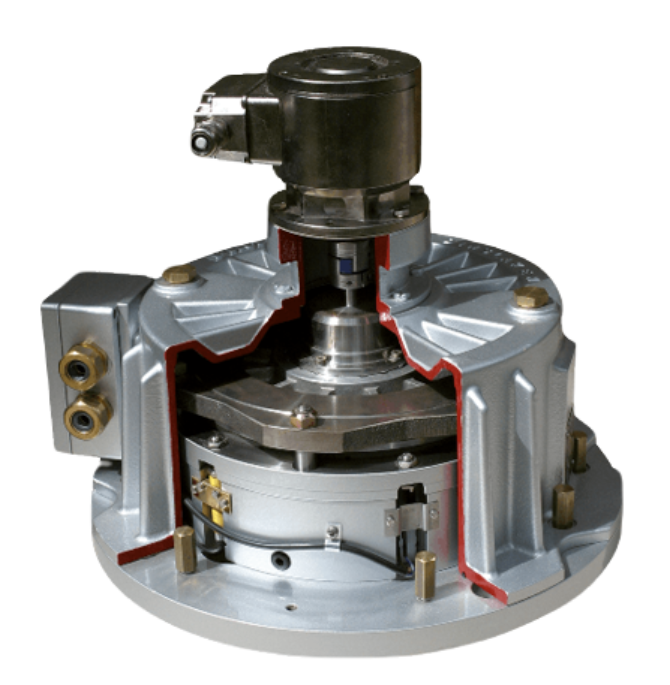

Electromagnetic brakes, often referred to as EM brakes, operate using magnetic force to apply braking torque. Their core components include a coil, armature, electromagnet, and friction surface. When energized, the coil generates a magnetic field that attracts the armature, pressing it against the friction disc and producing the necessary resistance to slow or stop motion.

These brakes come in multiple configurations—such as power-on, power-off, and spring-applied designs—each suited to different safety and operational needs.

An electromagnetic brake, also known as an EM brake, uses magnetic force to apply mechanical resistance. These electro-mechanical brakes rely on a coil, armature, and friction disc or pressure plate. When electric current is applied to the coil, it produces a magnetic field that pulls the armature against the friction surface, creating braking torque. This design allows the brake to be actuated quickly and disengaged when needed.

Electromagnetic brakes are available in a variety of brake models and configurations such as power-on, power-off, and spring applied brakes. Many of these brake designs include fail-safe mechanisms, ensuring the brake is applied during a power failure.

How does an electromagnet brake system work?

Electromagnetic braking systems operate using electromagnetic force. When current is applied to the coil, the resulting electromagnetic field draws the armature into contact with the disc, creating the friction necessary to transmit torque and stop movement. This power-on actuation is reversed when power is removed, using springs or magnetic release to disengage the brake.

The core components of these systems include:

- Coil: Applied to the coil, electric current activates the brake

- Armature: Creates friction against the disc

- Friction disc: Ensures braking torque and reducing wear

- Electromagnet: Generates the magnetic field

This setup ensures fast response, zero backlash, and accurate control—ideal for applications requiring high torque and reliability.

Features

30 years of experience

Extensive local inventory

Rapid delivery

Run your operations efficiently

SFB

The SFB series from Dellner Bubenzer is a high-performance electromagnetic disc brake built for demanding industrial applications. As a spring applied brake, the SFB engages mechanically during power failure, ensuring a fail-safe stop.

Key features:

- Compact design with high torque ratings

- Sealed to IP67 for environmental protection

- Friction surface designed for fast response and minimal wear

- Suited for use in cranes, conveyor belts, and steel processing

These brakes are commonly used in applications involving automation, where fail-safe performance and reliable actuation are critical.

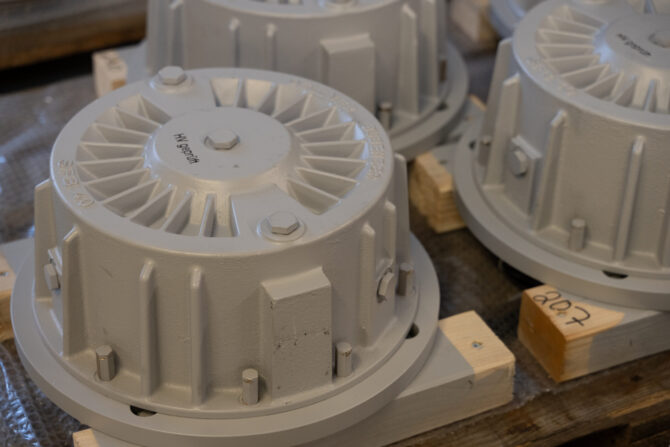

KFB

The KFB series enhances the functionality of the SFB, offering a broader range of high-performance features. As a spring applied electromagnetic disc brake, it provides consistent braking force even under extreme conditions.

Key features:

- Permanent magnets integrated for holding brakes

- Flexible mounting (horizontal/vertical)

- Suitable for winch manufacturers, robotics, and offshore systems

- Ideal for applications involving zero-backlash and fast actuation

The KFB’s robust design and high braking torque make it ideal for heavy-duty mechanical systems.

Applications of Electromagnetic Brakes

Typical applications include:

- Cranes and hoists – Applying mechanical resistance during lifts

- Wind turbines – Brakes are used for rotor holding and control

- Marine propulsion – Ensuring safe operation and docking

- Automation and robotics – Where accurate braking and torque control are essential

- Steel, mining, and construction – For machinery that requires spring applied brakes with high inertia control

These brakes make a significant difference in applications requiring frictional clamping force and systems requiring rapid disengage or power-off safety.

Key Benefits and System Design

Electromagnetic disc brakes offer several distinct benefits:

- Fast actuation and disengage time

- Braking torque mechanically applied with accuracy

- Fail-safe functionality with spring applied designs

- High-performance friction disc and zero-backlash capability

- Compression springs and permanent magnets for holding and actuation

Their versatility and system design flexibility make them ideal for both standard and custom installations.

Maintenance and Durability

Modern brake designs include IP67-rated housings for protection against dust and moisture. High torque electromagnetic brakes also include friction surfaces engineered to reduce wear, ensuring long service life. Periodic checks of coil integrity, armature alignment, and braking torque output help maintain system reliability.

At Euro HÜBNER, we assist clients with product selection, replacement parts, and ongoing technical support to ensure your system remains efficient and safe.

Why Choose Euro HÜBNER?

With more than 30 years in brake system supply, Euro HÜBNER is the go-to partner for:

- Advanced braking solutions for cranes, automation, and renewable energy

- Expert advice on torque ratings and applied brake design

- Distribution of reliable brake models from Dellner Bubenzer

- Fast response and flexible service tailored to your needs

We help you identify the right brake—electromagnetic, disc, spring applied, or permanent magnet—for every unique application.

Industries

Require any help?

Feel free to call or e-mail us, and we will get back to you as soon as possible.

Service & Repair

Euro HÜBNER Benelux B.V. provides high quallified service and repair solutions.

-

-

-