Due to recent changes in regulations from several certifying bodies, it is sometimes necessary to modify a winch intended for man-riding applications. Our sister company, Aandrijf Technisch Buro B.V., was approached by a client who required an upgrade to their winch for use in man-riding operations. The certifying body required the installation of a secondary brake directly on the drum, rather than on the same driveshaft where the main gearbox operates.

Innovative Solution to High Brake Torque Requirements

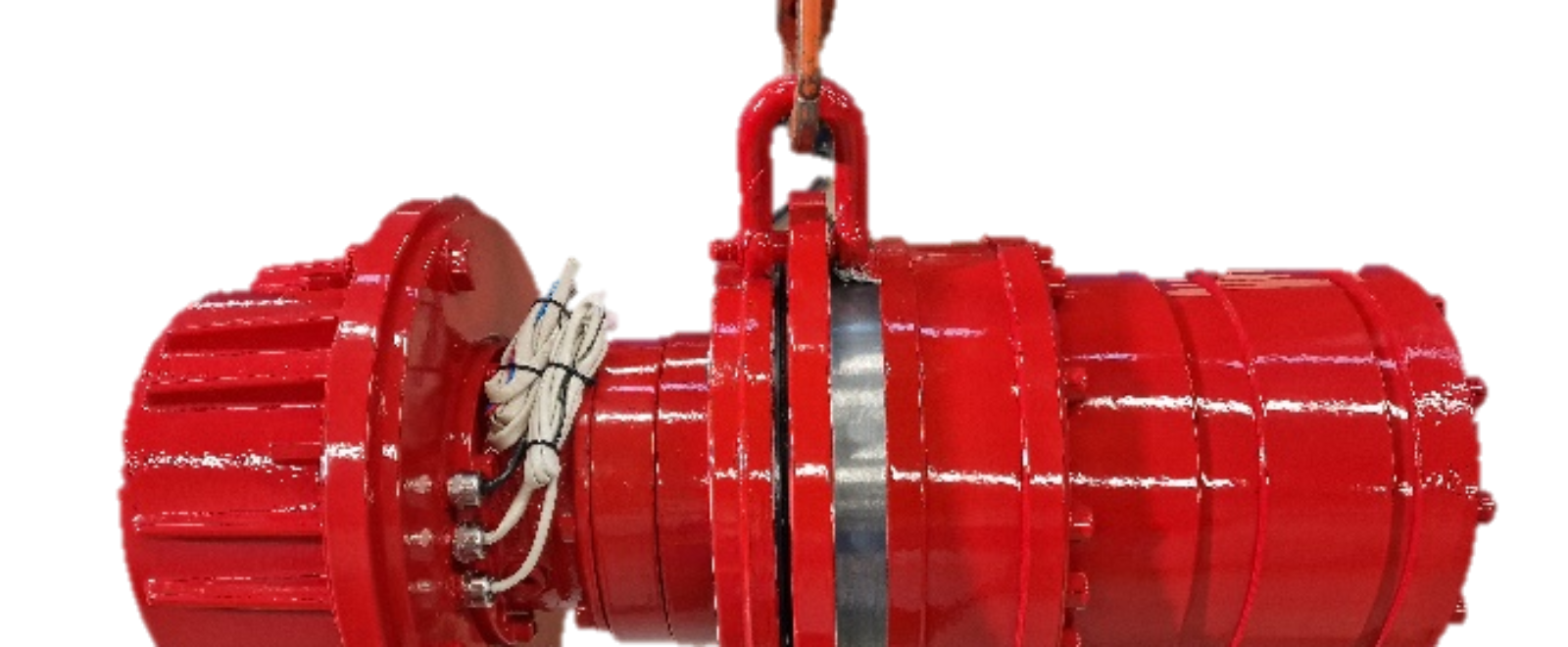

The required brake torque on the drum was quite high for an electromagnetic spring brake. To address this challenge, our customer chose to install a small winch gearbox inside the drum, on the side opposite the main gearbox, to reduce the torque required for the electric brake.

Fast-Track Project Execution

This project needed to be completed within a very short timeframe. Fortunately, Aandrijf Technisch Buro B.V. assembles Dinamic Oil winch gearboxes in their Venlo workshop, and we had the necessary electromagnetic spring brakes in stock, all with Type Approval certification. Together, we embraced this challenge. With assistance from the customer’s engineers and local machining shops, we built a gearbox with a customised input, intermediate flange, and bush to directly connect the electric brake.

Additional Features for Environmental Conditions

At Euro Hubner Benelux’s workshop, we incorporated an anti-condensation heating system due to the environmental conditions and installed a proximity switch to signal when the brake is lifted.

Completion Within 3 Weeks Despite Challenges

Despite it being the Christmas period, and the need to blast and paint the assembly with a three-layer offshore coating, we completed the project within just three weeks. This achievement is a testament to the power of teamwork—teamwork makes the dream work!