Our products

POG10DN1024I

OG71

- Type: Solid shaft

- Size: ø6 mm

- Output stage: HTL or TTL

- Flange size: ø58 mm

- Resolution: 100 … 1024 ppr

POG9

- Type: Solid shaft

- Size: ø11 mm

- Output stage: HTL or TTL

- Flange size: ø115 mm

- Resolution: 300 … 5000 ppr

POG83

- Type: Solid shaft

- Size: ø11 mm

- Output stage: Universal HTL/TTL

- Flange size: ø115 mm

- Resolution: 512 … 4096 ppr

POG10

- Type: Solid Shaft

- Size: Ø11 mm

- Output stage: HTL, TTL

- Flange size: Ø 115mm

- Resolution: 300 … 5000 ppr

HOG71

- Type Blind hollow shaft

- Size: ø12 mm and ø14 mm

- Output stage: HTL or TTL

- Flange size: ø60 mm

- Resolution: 64 … 2048 ppr

HOG10 – KLK

- Type: Blind hollow shaft or cone shaft

- Size: ø12...20 mm (blind hollow shaft) ø17 mm (cone shaft 1:10)

- Output stage: HTL or TTL

- Flange size: ø105 mm

- Resolution: 300 … 5000 ppr

HOG10-KLK AX

- Type: Blind hollow shaft or cone shaft

- Size: ø12...20 mm (blind hollow shaft) ø17 mm (cone shaft 1:10)

- Output stage: HTL or TTL

- Flange size: ø105 mm

- Resolution: 300 … 5000 ppr

Did you not find what you were looking for?

Contact us and we will look for the right solution together!

InquireAccessoires

At Euro HÜBNER Benelux B.V., we offer a wide range of encoder incremental solutions from trusted manufacturers such as Baumer holding AG, designed to meet the demanding requirements of heavy-duty and high-precision industries across the Benelux.

Our portfolio includes incremental rotary encoders, incremental optical encoders, incremental shaft encoders, and incremental hollow shaft encoders, all engineered for outstanding durability and accuracy in industrial environments.

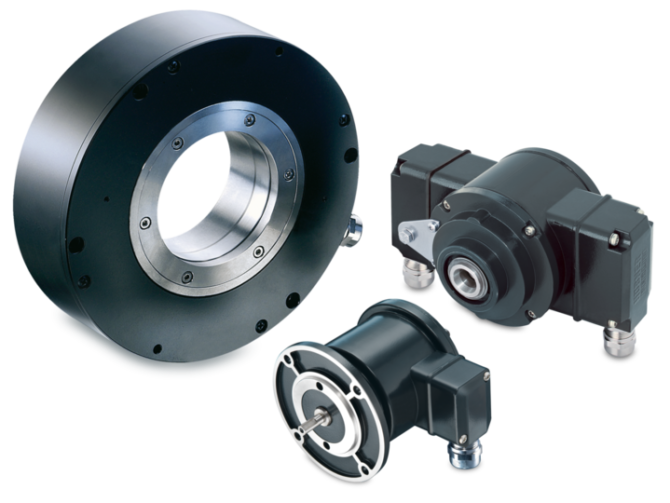

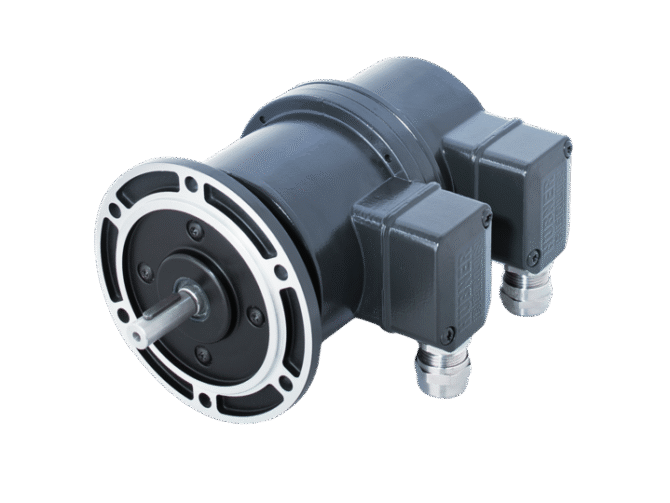

A selection of encoders – incremental models – can be viewed above.

What is an incremental encoder?

An incremental encoder is a type of rotary encoder that converts the angular motion of a shaft into digital or analogue signals. It measures changes in position by generating a series of pulses per revolution. These pulses are counted by a controller, which then calculates position and speed.

Because an encoder incremental only provides change information, the machine’s control system determines its reference position through a brief homing process at start-up. This makes incremental encoders a cost-effective and flexible solution for a wide range of industrial applications, from manufacturing and robotics to process control and drive systems.

How incremental encoders work

Encoders incremental operate by producing a pulse signal as the shaft rotates. Each pulse corresponds to a specific angular movement, allowing the control system to measure rotational speed and direction.

A typical encoder includes:

- A disc with evenly spaced markings or lines (optical or magnetic)

- A sensor that detects these lines and generates A and B channel signals

- Optionally, an index (Z) channel for precise reference positioning

The output signal can be transmitted through electrical interfaces such as TTL, HTL, or differential line drivers, depending on the system’s specifications. The number of pulses per revolution (PPR) defines the resolution of the encoder. The higher the PPR, the more precise the measurement.

Incremental encoder types

Incremental encoders can be used in a wide range of applications. Euro HÜBNER Benelux B.V. supplies several encoder incremental models designed for different mechanical and environmental needs:

Incremental shaft encoders

These encoders provide a solid shaft design for secure coupling with motors and drive systems. Incremental shaft encoders are commonly used in servo systems and factory automation, where high-precision position feedback and robustness are essential.

Incremental hollow shaft encoders

With a compact, space-saving design, incremental hollow shaft encoders mount directly onto the motor shaft without couplings. This design reduces mechanical vibration and simplifies installation. Ideal for compact machinery and conveyor systems, they combine reliability with easy mounting and alignment.

Incremental optical encoders

Incremental optical encoders use light-based detection for extremely accurate signal generation. They are perfect for applications requiring high precision, minimal error margin, and repeatable positioning, such as robotics, CNC machines, and electronic assembly equipment.

Applications of incremental encoders

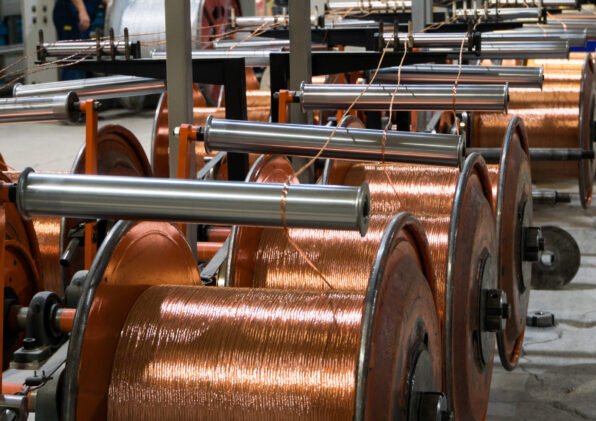

Incremental encoders are used in a wide range of industrial applications where accurate speed or position measurement is vital. Typical sectors include:

- Steel, paper, and wood industries: providing feedback for high-torque motors and rollers.

- Cranes and lifting systems: ensuring safe rotation and load positioning.

- Packaging and printing machines: enabling precise linear and rotational synchronisation.

- Motion control systems: used in combination with drives and PLCs for real-time feedback.

Key benefits of using incremental encoders

- High accuracy: Provides detailed pulse counts for precise position and speed measurement.

- Fast response: Immediate feedback allows for dynamic motion control.

- Flexibility: Wide selection of mounting options, including shaft and hollow-shaft designs.

- Durability: Designed to withstand shock, vibration, and temperature variations.

- Compatibility: Available with standard electrical interfaces for easy integration into control systems.

Compared to an absolute encoder, an incremental encoder focuses on relative motion rather than fixed absolute position, making it ideal for systems that do not require stored position data after a power failure.

Why choose Euro HÜBNER Benelux B.V.?

At Euro HÜBNER Benelux B.V., we combine deep technical expertise with a commitment to reliability and service. We stock a comprehensive range of encoders incremental to ensure rapid availability and project continuity. Our specialists help you select the right model based on your application requirements, ensuring perfect integration into your system.

What we offer

- Large stock of incremental and absolute encoders ready for delivery

- Fast dispatch within 24 hours across the Benelux region

- Technical advice for product selection and installation

- Testing, validation, and repair services for your encoders

- Custom solutions for unique industrial applications

Looking for a custom solution?

We want to help you!

Contact

Benefits

Large stock of products

In our warehouse in Venlo, we maintain a large stock of incremental and absolute encoders, tacho generators, brakes, brake parts and force measuring systems. Our company is based in Venlo, in the centre of the Benelux. Due to this location, we are able to deliver on a very sharp time schedule. When urgency is requested, we can deliver within 24 hours to your company in the Benelux, or even arrange a taxi for delivery within a few hours. Because we keep such a large stock in our warehouse, we are able to process and deliver your order usually very fast.

Total solutions

Euro HÜBNER Benelux B.V. offers a range of total solutions to meet to the specific needs of our clients. These solutions encompass various aspects from technical consultancy to product selection, installation and support services.

Design and Engineering

We assist clients in the design and engineering phase of their projects. Our team of experts collaborates closely with our clients to understand their requirements and develop customized solutions that meet their specific needs.

Product testing and Validation

Our company conducts rigorous testing and validation procedures to ensure that the products meet industry standards and regulatory requirements. This helps in verifying the quality, durability and reliability of the solutions we provide.

Customized Solutions for Various Industries

Euro Hübner Benelux B.V. serves clients from diverse industries, including steel industry, paper industry, marine on- and offshore, motion control, industrial and construction industries. We customize solutions to meet the specific demands and challenges of each industry, providing reliable and efficient products.

Quality Assurance

Euro HÜBNER Benelux B.V. is committed to delivering products and services of the highest quality. We adhere to stringent quality control measures throughout our operations, from design and manufacturing to installation and support. By prioritizing quality assurance, we aim to provide customers with reliable, durable, and high-performing solutions.

Markets & Technology

Require any help?

Feel free to call or e-mail us, and we will get back to you as soon as possible.

Service & Repair

Euro HÜBNER Benelux B.V. provides high quallified service and repair solutions.

-

-

-