In advanced automation and industrial applications, the need for precise, reliable communication between devices is greater than ever. One of the most trusted solutions for position feedback is the SSI encoder – a type of absolute encoder that uses the Synchronous Serial Interface (SSI) protocol. But what exactly is this interface, and why is it so valuable in today’s motion control systems?

In this blog, we’ll explain how this type of encoder works, explore the key benefits of the SSI protocol, and introduce several models Euro HÜBNER Benelux B.V. offers, trusted for their high-resolution output, robust construction, and seamless integration.

What is an SSI encoder?

An encoder that uses the SSI interface is a digital absolute encoder that communicates position data using synchronous serial transmission. The interface is designed for point-to-point connection between the encoder and a controller or PLC.

This encoder outputs a unique binary value for each shaft position, providing accurate position information, even after power loss. Unlike incremental devices, which output signals based on motion, these encoders transmit absolute position in a fixed word format using the synchronous clock signal from the master controller.

Such encoders are typically found in industrial environments where system integrity and reliability are key.

How the SSI Protocol Works

The SSI protocol uses a differential transmission method for serial data transfer. It operates with a pair of wires, clock and data, forming a simple but effective connection. Here’s how it functions:

- A controller (master) sends clock pulses to the encoder (slave).

- The encoder transmits binary position data in synchrony with the clock signal.

- After transmitting a complete word, the interface resets until the next cycle.

Because the communication is synchronously timed, the transmission ensures high data integrity and noise immunity – ideal for busy control systems. The protocol can also support extended cable lengths and twisted pair cables, particularly when implemented with RS-422 standards.

Advantages of Using the SSI Interface

Using a synchronous serial interface offers several technical and practical advantages:

Absolute Positioning

The encoder provides a specific value for each position, removing the need for referencing after power interruptions. This is ideal for safety-critical applications.

High Signal Integrity

Differential transmission and synchronised timing reduce interference, even in environments with frequent electrical noise or multiple devices operating in parallel.

Simplified Wiring

The point-to-point connection is made with just a pair of signal wires, reducing complexity, weight, and failure points in wiring harnesses.

Flexible Data Length

The protocol supports different word lengths, allowing it to represent multiple resolutions depending on application needs.

Fast, Consistent Communication

Thanks to synchronous transmission, data is always delivered at a constant rate, without timing jitter – crucial for real-time control applications.

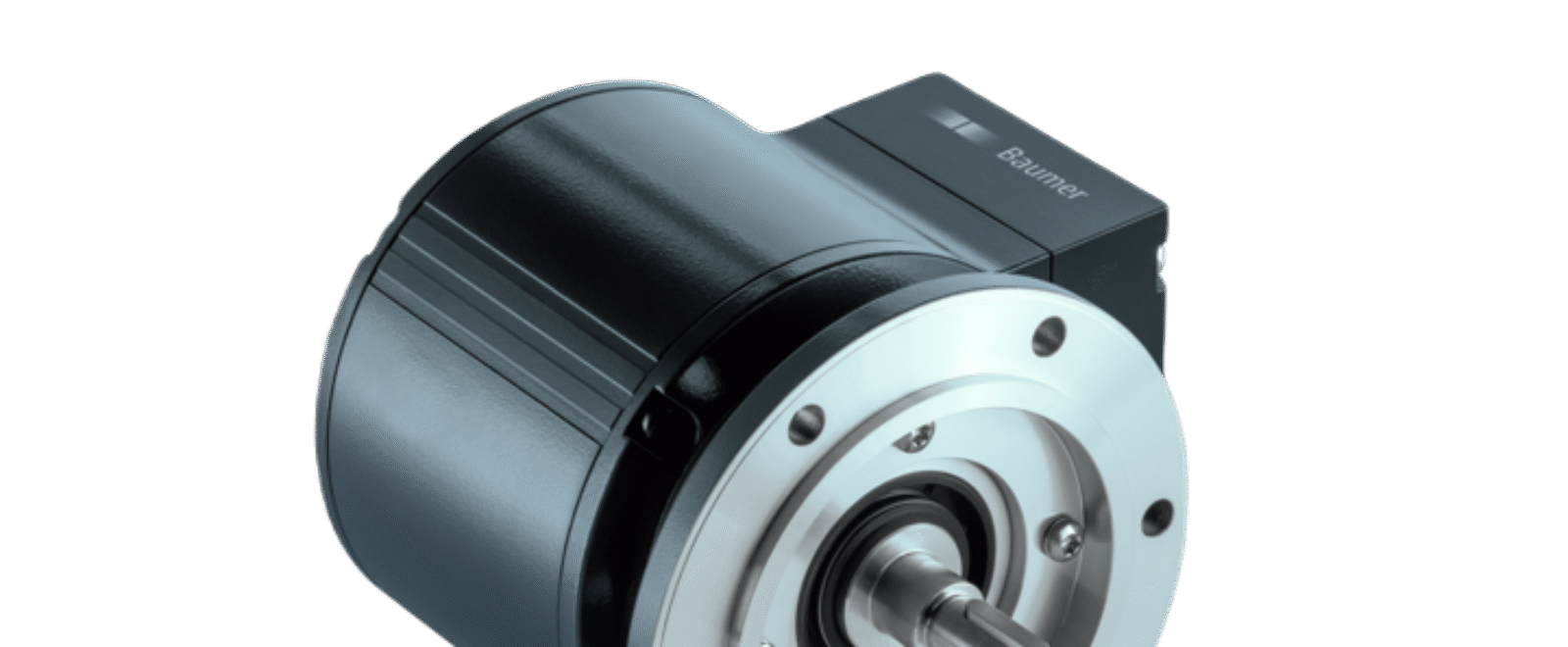

Featured SSI encoder models from Euro HÜBNER

We offer a range of reliable, high-performance models that use the SSI interface. These are used in industrial automation, cranes, mobile equipment, and more.

PMG10 SSI

The PMG10 SSI is a compact encoder that delivers accurate digital output in harsh conditions. Ideal for installations with limited space and requiring a long service life.

HMG10 T SSI

The HMG10 T SSI multiturn model is designed for offshore and marine systems. Its rugged construction and versatile mounting options make it a top choice for winch and lifting systems.

HMG10 B SSI

The HMG10 B SSI delivers stable encoder data under extreme vibration and temperature fluctuations. Its protective design ensures safe operation in mobile and heavy-duty machinery.

These encoders belong to our broader absolute encoders portfolio, designed for precision, longevity, and operational safety.

Applications in motion control systems

Encoders using SSI are widely used in motion control systems where timing, resolution, and output accuracy are critical. In a typical setup:

- The controller receives a fixed-length word representing the exact shaft position.

- The system can react instantly, adjusting speed, torque, or load based on accurate feedback.

- This enables smooth automation and safe emergency stops.

In many systems, these encoders are paired with electromagnetic brakes to ensure secure stopping and holding, especially in vertical or dynamic loads.

SSI vs other encoder interfaces

How does the SSI protocol compare to other encoder interfaces?

- Incremental: Transmits pulses based on movement and requires a reference cycle after power loss.

- Parallel: Requires multiple wires for each bit of output, leading to bulky and error-prone wiring.

- Fieldbus (PROFIBUS, PROFINET): More complex and supports networked communication, but with slower reaction time for basic feedback.

The SSI interface strikes a balance between precision, simplicity, and durability.

For a full comparison of available technologies, check out our blog on types of encoders.

Conclusion

Encoders using the synchronous serial interface (SSI encoders) are a reliable, efficient solution for absolute position feedback in demanding environments. They provide noise-resistant, point-to-point data transmission with minimal latency and high precision.

Whether you’re working in mobile machinery, steel processing, port technology, or crane control, Euro HÜBNER Benelux B.V. offers proven encoder models that deliver under pressure.

Need support choosing the right device? Our specialists are here to help. Contact us for personalised advice or to request specifications.

For more background, read our explanations on absolute encoders, the difference between incremental and absolute encoders, and motion control systems.