Advantages

- High resistance to sea conditions - No corrosion with salt spray or salt surface drying due to the high-quality stainless steel housing - Tight during temporary water overflow or high-pressure cleaning thanks to a tightness concept and optimized mechanical connections - Resistant to shocks and vibrations caused by waves or docking maneuvers due to its robust housing and high-quality ball bearings

- Maximum machine availability - Long-term sealed design prevents the entry of water and humidity - Longer service life proven by upstream stress tests and only subsequent IP tests - Minimized service costs, as service is required less frequently

- Superior verification through intensive tests - Expanded test series beyond DNV-GL - Additional stress tests with shocks, vibrations, salt spray, and dryingIP tests only after previous stress tests

- Simplified ship and system approval - Version with DNV-GL approval - Tested in accordance with the standard IP 66 - Also passes conditions of IP 67 and IP 69K

Product options

Technical data

| Supply Voltage | 4.75...30VDC(HTL/TTL) |

| Shaft Type | Solid shaft ø11 mm |

| Pulses per Revolution | 512…4096 |

| Sensing Method | Optical |

| Output Signals: | A+,A-,B+,B-,R+,R- |

| Protection EN 60529 | IP 66, IP67, IP69K |

Accessoires

HEAG 151, 152, 153, 154

- High precision measurement capabilities, ensuring reliable and accurate data collection.

- Robust construction suitable for use in harsh industrial environments.

- Compact design, allowing for easy integration into various systems and machinery.

- Fast response times, enabling real-time monitoring and control.

- Versatility in applications, from object detection to distance measurement, providing flexible solutions for different needs.

- Low maintenance requirements, resulting in reduced downtime and operational costs.

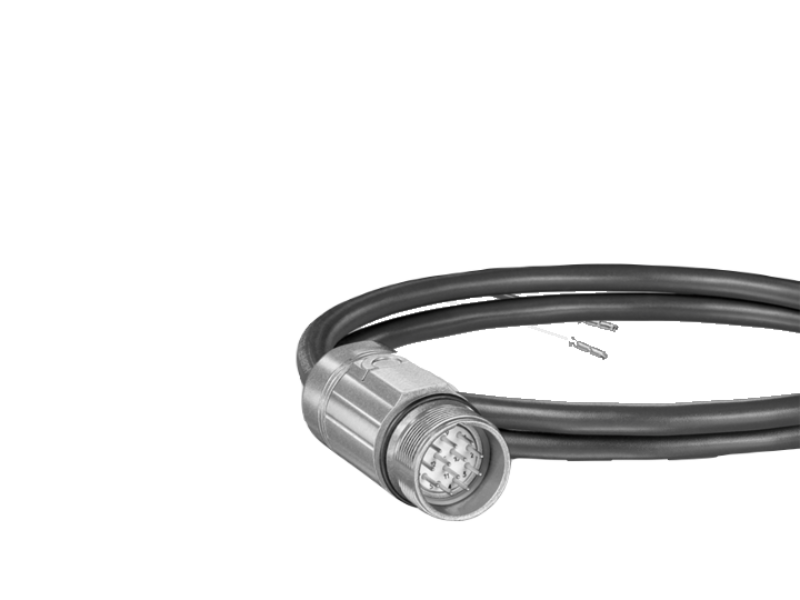

Cable HEK8

- High durability and robustness, capable of withstanding harsh conditions and mechanical stress.

- Excellent signal integrity, ensuring stable and consistent data transmission for critical applications.

- Flexibility and ease of installation, allowing for seamless integration into complex systems.

- Resistance to environmental factors such as temperature fluctuations, moisture, and chemicals, enhancing longevity.

- Suitable for a wide range of industrial applications, from machinery to control systems, providing versatile connectivity solutions.

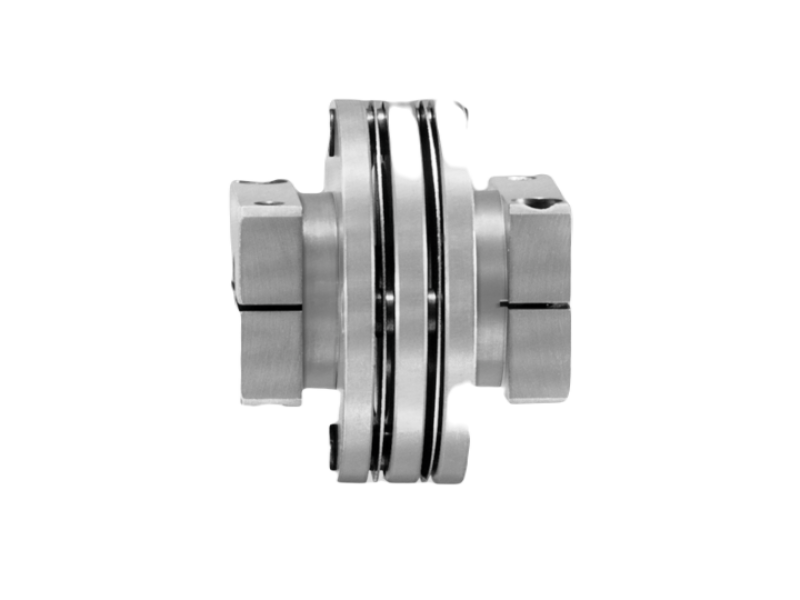

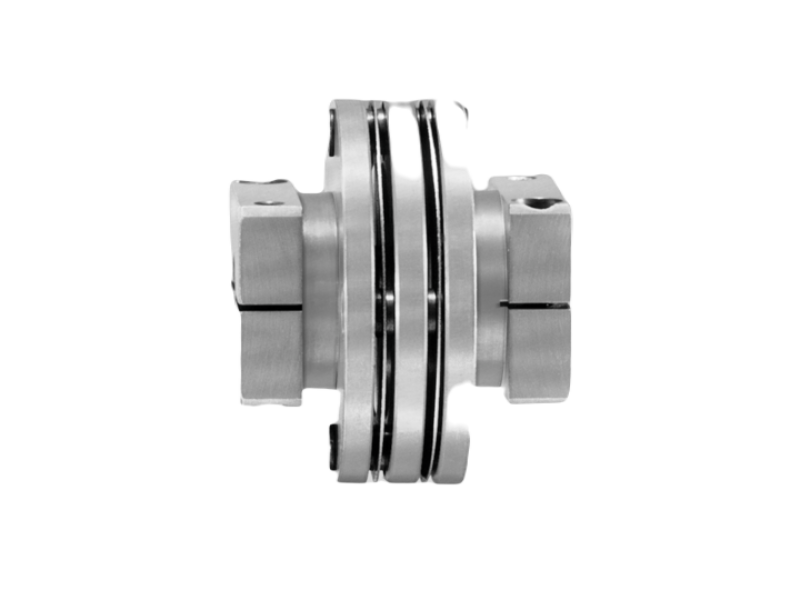

Spring disk coupling K35

Spring disk coupling, which combines the necessary torsional stiffness with the ability to compensate for axial displacement which occurs especially through heat expansion of the drive and the play backlash of the ball bearings.

More information

Spring disk coupling K50 Isol. 11S-11S

Spring disk coupling, which combines the necessary torsional stiffness with the ability to compensate for axial displacement which occurs especially through heat expansion of the drive and the play backlash of the ball bearings.

More information

Spring disk coupling K50 isol. Shaft Ø11 …16mm

Spring disk coupling, which combines the necessary torsional stiffness with the ability to compensate for axial displacement which occurs especially through heat expansion of the drive and the play backlash of the ball bearings.

More information

Spring disk coupling K60

Spring disk coupling, which combines the necessary torsional stiffness with the ability to compensate for axial displacement which occurs especially through heat expansion of the drive and the play backlash of the ball bearings.

More informationDownloads

POG 83 Datasheet

Download pdf (580 KB)POG83 extra information

Download png (182 KB)Industries

Contact us

Can’t find the desired product or do you need advice? Send us an email with the product photo (like the example below) and we will assist you with the right solution. You can also use the form to send us the photo.